Isolation Verification proves that all sources of energy are removed from equipment prior to conducting maintenance works. Done correctly it eliminates the risk of the equipment starting while being maintained and therefore injuring people or damaging plant.

Redbusbar Electrical Isolation Verification

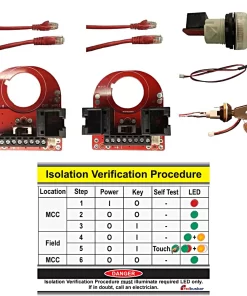

Redbusbar offers solutions for lockout verification performed at both a central location (MCC Motor Control Centre or Switchboard) and a field location (local to the isolated equipment). When isolating plant at a central location, a risk exists that an Isolation Officer may isolate the wrong machine or a worker may unintentionally work on energised equipment.

| Verification Solutions | Verification Location | |

| Motor Control Centre | Field / Local | |

| DeadEasy | • | |

| DeadEasy + RightSwitch | • | • |

| SwitChek | • | |

Electrical Isolation Verification

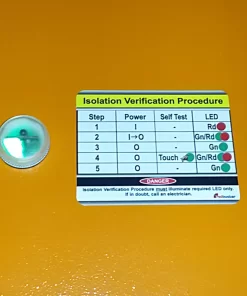

Proof of isolation on electrical powered equipment means confirming that an electrical switch, circuit breaker or disconnect powering the machine is off or open. Lockout Tagout Verification methods include:

- Voltage measurement at the load side of the switch – Electrician Test for Dead, Voltage Indicators (DeadEasy), Live Line Indicators (LLI), Absence of Voltage Testers (AVT)

- Visual check – Plug and Sockets, Visual Break Isolators

- Attempting to start the equipment after isolating – Try Start / Attempt Start / Bump Start

- Insulation resistance measurement across the switch contacts – Electrician high voltage resistance test, Automatic high voltage resistance test (SwitChek)

Care is needed when selecting a LOTO verification method. The method integrity, location, complexity and cost vary greatly. Learn more in the Technical Paper – Confirming Electrical Isolations

Isolation Verification

Isolation Verification

Isolation Verification