3 Phase Isolation Switch Tester / Switch Resistance Tester

$1,072.50 incl. GST

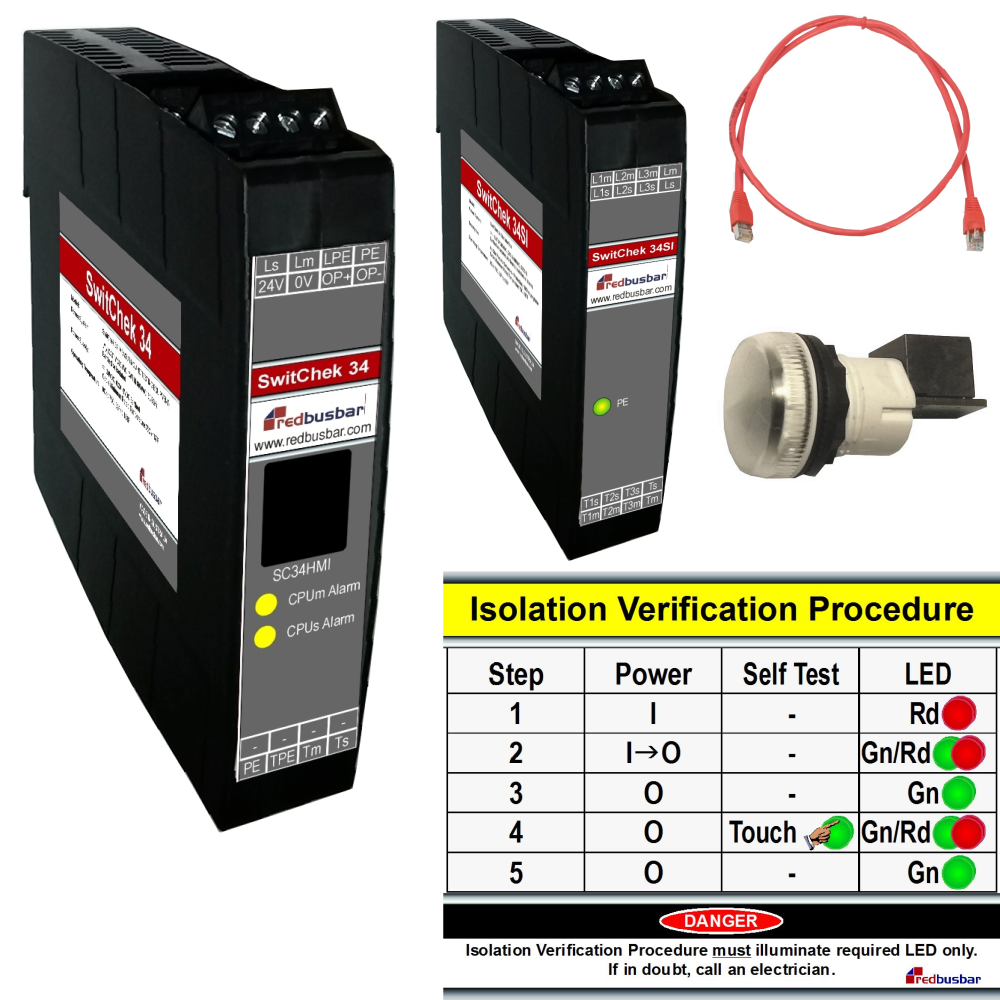

Electrical Isolation Confirmation / Isolation Verification, Insulation Resistance Test Device – Kit for 1 Isolation Switch Including One SwitChek (SC34), One SwitChek Star Interface (SC34SI) One SwitChek Human Machine Interface (SC34HMI), One SwitChek Human Machine Interface cable (SC34HMIC) for 1 Isolation Switch

SwitChek is a 3 phase, Isolation Switch Tester. As a switch resistance tester it confirms that an isolation switch or circuit breaker does not pass electrical voltage or current when isolated.

SwitChek provides any worker with a simple and safe method of verifying field isolator or local control panel based, electrical isolations, before conducting mechanical maintenance.

SwitChek Operation Video

SwitChek Features Video

Features

Unique SwitChek 34 features include:

- Positive indication on isolation

- Self test function

- Suits field isolator applications

It’s different to a Visible Break Isolator as Isolation indication is prominent and clear, at a much lower cost

Details

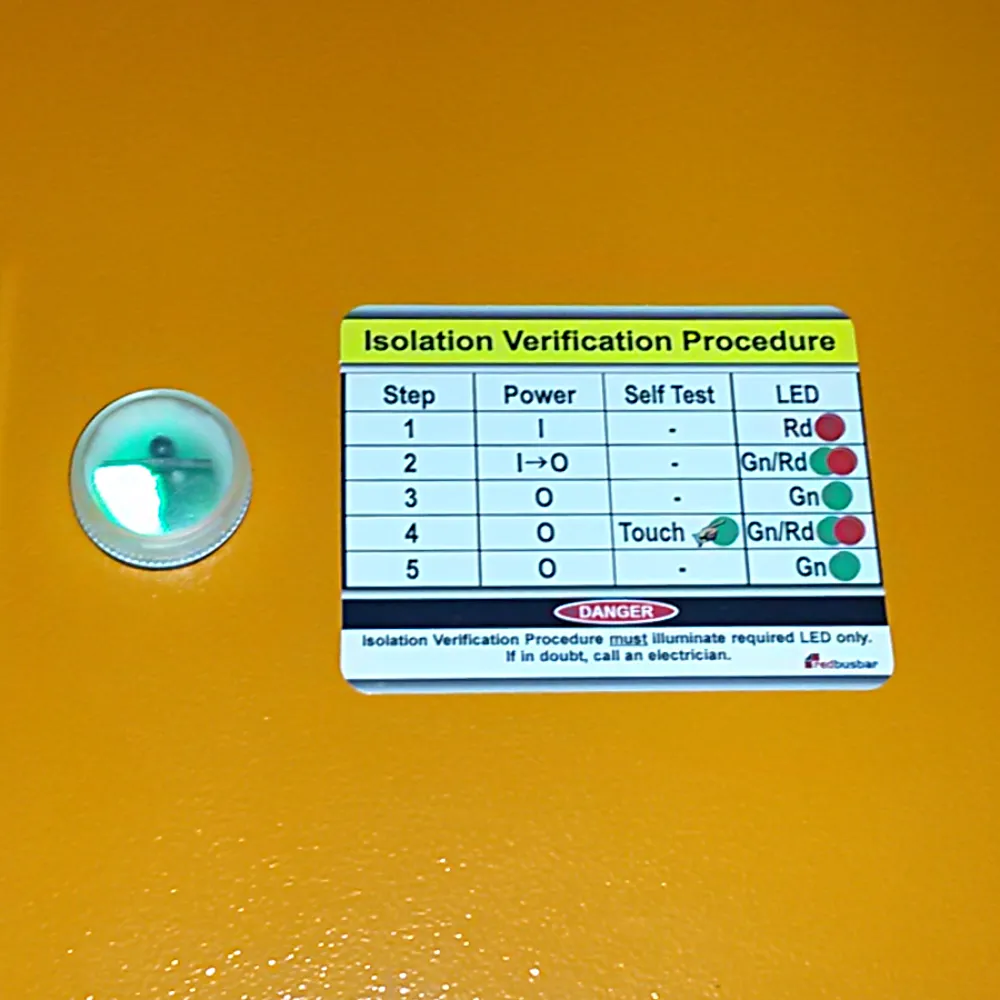

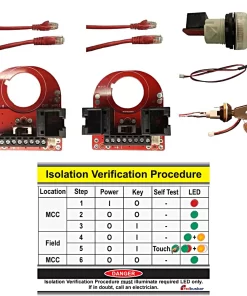

Positive Indication on Isolation

The green LED is illuminated when the switch is isolated / open. This rules out the question – Did the lamp fail as I turned the switch off or is the led indicating that the switch is really off?

Self Test Function

Self Testing is performed automatically:

- On SwitChek 24VDC power up, and

- Every closed to open (red to green LED) switch transition, and

- Periodically during opened isolator (green LED) indication.

This automatic testing is in addition to the manual testing capabilities available while the green LED is illuminated. Every self test performs a sequence of tests as follows:

- The master channel generates a test voltage and measures the impedance of the slave channel which the slave channel expects to detect

- The master channel removes the test voltage which the slave channel is expects not to detect

- The slave channel generates a test voltage and measures the impedance of the master channel which the master channel expects to detect

- The slave channel generates a test voltage which the master channel is expects not to detect

This 2 second test sequence results in red and green LED flashing. The self test confirms the correct function of the star interface, logic processing unit, output LEDs and all interconnecting wiring is confirmed. A true safety rated self test!

Volt Free, Power System

The line side of an isolation switch in a field control panel or local control panel is often de-energised when locking out. So voltage measurement or voltage indication on the load side of the switch produces inconclusive isolation verification. SwitChek solves this by applying its own voltage to perform an insulation resistance test. It functions whether the line side of the switch is energized or de-energized.

Digital Output

Active on green LED. Allows you to log the isolated event and/or enables control system indication of the isolated

equipment.

Other Benefits

- Allows non-electricians to perform an “Insulation Resistance” style test on an electrical circuit.

- Functions whether the line side of the isolator is energized or de-energized

- Is simple to use

- Is in your face indication. Visible Break Isolators (VBI) require a deliberate viewing effort by trained personnel who are detailed inclined

- When combined with a load break switch, is inexpensive compared to Visible Break Isolators

- Is high integrity compared to manual verification methods such as Try Start

- Is simple to install. 2x25mm wide DIN rail mount electronics, HMI incorporating power indicator leds and self test request all in one only 22.5mm panel lamp cut-out

- Has wide application. SwitChek is suitable for new and retrofit installations and dusty, low and high ambient light environments

- Is flexible. SwitChek, 3 phase isolation switch tester allows subsequent verifications without reversal of the isolation ie accommodates late working parties

- Reduces exposure to arc flash / faults. The isolated state of phase conductors is known before panel doors are opened to conduct tests

SwitChek 3 phase Isolation Switch Tester Background

SwitChek tests an isolation switch to establish whether the switch is both closed and opened (on and off). SwitChek uses Super Bright LEDs so the test result is clear and obvious. SwitChek provides non-electrical people with a simple and safe insulation resistance measurement for Field Isolator or Local Control Panel electrical isolations before conducting mechanical maintenance. In addition, confirmation of the isolated state of the load side ac phase conductors inside a cabinet may reduce the level of Arc Flash PPE required to open the cabinet door.

It is simple and fast to use. No licenses are necessary. Anyone can operate SwitChek, disconnect tester.

SwitChek’s focus is low voltage (< 1000V / 1kV AC phase to phase) systems. SwitChek is local isolator / local control station mounted so that one SwitChek switch tester is dedicated to one isolation switch. It is ideally suited to installation within a field motor isolator where it is likely that the line side phase conductors are deenergised at the time when isolation verication is to be performed.

Package Includes

- SwitChek DIN Rail Mounted Electronics (SC34)

- SwitChek DIN Rail Mounted Star Interface (SC34SI)

- SwitChek Human Machine Interface and Procedure Label (SC34HMI)

- SwitChek Human Machine Interface cable (SC34HMIC)

- Installation and operation manual

FAQ

Mainly because electrical isolations, even if the correct switch is turned off and locked, are not always sound.

We generally think that once we have turned off and locked an isolating switch or circuit breaker that the equipment is 100% safe to access. Not so, many, many switches from the largest manufacturers have failed in a mode that allows switches to pass current in the “off” position. The switch failures have caused fatalities in Australia and in the USA. The fatalities have motivated legislators towards the need to verify isolations. This legislation now requires isolation confirmation or verification of isolation. Many tests have been developed to test isolating switches. Some tests that are used today are cumbersome and some are potentially misleading.

Switch failure modes that allow the passing of current in the off position include:

- Welded switch contacts.

- Worn handles that fail to rotate the switch mechanism when the handle is rotated.

- Misaligned handles that fail to engage with the “handle to switch” connecting shaft.

- Switch bypass faults – cable-to-cable faults.

Perhaps there is a message in the fact that all major manufacturer’s of isolating switches now incorporate Visible Break Isolators (VBI) in their range!

SwitChek 3 phase Isolation Switch Tester was designed to:

- Provide non-electrical people with a simple and safe method of verifying field based, electrical isolations before conducting mechanical maintenance.

- Provide operator confidence in the reported test result through the use of a operator initiated, self test function.

- Be implemented in new and retrofit applications by being inexpensive to purchase and simple to install.

- Be a universal solution. SwitChek operates whether the conductors are electrically alive or dead and is not affected by electrically noisy environments.

Manual Isolation Testing involves using an insulation resistance tester (Megger) to report the fact that there is no passage, via the cabling in the circuit under test, between the line side and load side of the isolating switch. It tests both the switch and the connected cabling. However, if the line side of the switch is alive the person performing the test is at risk. In most cases the Megger is simply not rated to protect the person performing the test. Informed companies have recognised this exposure and test using a multimeter instead. Of course mutimeters do not generate a typical service voltage so they do not stress test the switch.

Yes, but only if you perform less than 1 isolation per month on an inpidual isolator. In this case the cost of purchasing SwitChek and installing a SwitChek Interface is more expensive than paying for an electrician to manually confirm an isolation. This cost comparison is quite conservative. What’s not included are the costs associated with maintenance/construction team waiting for the electrician to arrive. In addition, the cost assessment is based on the first year’s costs. Of course in the second and subsequent years SwitChek costs are negligible whilst manual confirmation of isolation costs are ongoing.

In summary, if you perform 1 isolation every month on an individual isolator, SwitChek payback is one year. Of course the cost assessment does not highlight which method of isolation confirmation is technically superior!

SwitChek isolation switch tester provides greater testing flexibility than DeadEasy LED phase indicator as it can conduct a test whether or not the line side of the switch is alive or dead. This is important for field isolators as the line side of the switch is most likely to be deenergised at the time of testing. DeadEasy requires the line side of the switch to be alive at the time of testing. As such, it is most suitable for switchboard or motor control centre verification of isolation.

The “Try Start” isolation procedure aims to determine, through the use of local or remote starting methods, that the isolation switch prevents the motor from starting. This is useful in allowing non-electricians to determine whether it is safe to perform mechanical maintenance on a motor e.g. grease bearings. The procedure for the “Try Start” method is largely dictated by the facilities available for isolation and motor control and their locations.

The disadvantages of this approach are as follows:

- The “Try Start” method can’t always be used because it can be inconclusive. The method relies on confirming that the machine will not operate when a start request is issued. A blocked screw conveyor, deadheaded positive displacement pump, jammed mixer, jammed crusher or jammed saw blade will not move when you try to start it even when started with the power on!

- In most circumstances the “Try Start” method used does not actually stress test the isolation switch. In fact, it tends to prove that the control circuit is inhibited in some way eg emergency stop operated, incorrect mode (local/remote). The problem with this is is that it is the isolation switch that is locked. This means that later correct operation of the control circuit could reveal a faulty isolation switch with dangerous consequences.

- The “Try Start” method often contains between 8 and 16 steps. Some of our clients believe that it is unrealistic to expect operational personnel to perform this procedure or even to perform it correctly on each and every occasion. In essence, they feel that in the event of a workplace accident that a judge would see it this way also.

- The procedure can be complex and it changes from plant to plant which makes it necessary to conduct special and regular training.

- The “Try Start” method maybe inconvenient to use due to control interlocks. That is, several other items may be required to start before starting the equipment of interest. Because of this arrangement confirming the isolation is sometimes abandoned.

This approach has been trialed before by our clients and generally takes the form of fixed pilot lamps that can be read by a non electrician. The thinking being that prior to initiating the isolation all lamps are illuminated and after performing the isolation all lamps are extinguished. This result is taken as being a confirmed isolation.

The disadvantages of this approach are as follows:

- Poor pilot lamp to neutral connections yield the risk of shock voltages on the isolated side of a healthy switch. This point alone is reason enough not to pursue pilot lamps as it leads to potential electric shock situations.

- Using a strict testing approach, which is what is required when confirming an isolation, the approach to achieving a high integrity test result involves testing the lamps, testing the switch, testing the lamps = confirmed result. Clearly, when using pilot lamps, the last “testing the lamps” step cannot be conducted without reversing the isolation or installing costly self-test circuitry. This defeats the purpose of the isolation in the first place! This scenario demonstrates how a blown lamp could yield an incorrect confirmation of isolation result.

- Lamps regularly fail due to vibration. Operating a switch handle causes significant transient vibration.

- Short lamp life when used on variable speed drive (VSD, VVVF) or soft starter circuits. Harmonic currents use the lamps as a path to earth which leads to early lamp and LED failures. Sometimes within weeks!

- If the line side of the isolation point is dead, phase indication as a means of confirming an isolation cannot be performed.

If you need more convincing download a copy of the “Confirming Electrical Isolations” white paper on the Isolation Verification, Category page.

Visible Break Isolators (VBI) report the fact the isolating switch is open. However, they are large, expensive and disruptive to production when installing. Given the fact that they also provide no protective function they really do not provide a viable solution for MCC (Motor Control Centre) applications.

This arrangement is supported by AS3000 so long as certain circuit conditions are complied with. AS3000:2000 Cl 2.4.4.4 requires that:

- The length of the circuit is less than 3m.

- The circuit has no branch circuits.

- The conductors are not located in the vicinity of flammable materials.

- The conductors are mechanically protected by being located in a metallic wiring enclosure.

The power cable and the SwitChek measurement cable could be crimped together in a single boot lace pin, ring terminal or lug. The crimped connection then fits easily into/onto the switch terminal. In the case of larger power circuit conductors or busbars we recommend cable tieing lip blade terminals to the power circuit cable lugs or bars.

Firstly, SwitChek 3 phase Isolation Switch Tester is designed to withstand Cat III 415V installations in accordance with IEC 61010 . This means that it is suitable to withstand overvoltages sometimes experienced on power circuits. The method for achieving this performance is by the use of sufficient creepage and clearance distances as well as using componentry certified to provide this level of protection.

Secondly, should an internal fault develop within SwitChek, the SwitChek Interface incorporates PPTC resettable fuses which have an abient temperature resistance >1kOhm. This means a maximum fault current <1A will prevent an arc fault and severe SwitChek damage.

Thirdly, SwitChek is contained in a double insulated, fire retardant, polycarbonate dust proof and water proof (IP66) enclosure. It is mechanically robust.

We know that SwitChek will be expensive to implement on every switch. However, if you decide that proof of isolation is important to you and your company, manual testing and Visible Break Isolator (VBI) approaches are generally more expensive.

Our suggestion is that you start by identifying the isolation switches in your plant that present the most risk to personnel. That is, the switches that:

- Are used to frequently isolate plant for maintenance, cleaning or inspection access, and switches that ….

- Isolate equipment that people climb into or major portions of their body are inserted into. That is, it has the potential to seriously injure or kill.

Start with providing a solution for these equipment items first. Alternatively, you risk becoming overwhelmed by the task at hand and doing nothing!

Whilst it has been a Legal requirement in Queensland, Australia since 1994 to confirm isolations on all equipment, the following equipment generally exposes the personnel to greater access (hence exposure to severe injury or death) when being maintained:

- Printing Press.

- Jaw Crusher.

- Wood Chipper.

- Cut-off Saw.

- Conveyor.

- Forging Machine.

- Ball Mill.

- Ribbon Blender.

To our knowledge, no one! SwitChek 3 phase Isolation Switch Tester is a patented device.

No. The test voltage generated is floating with respect to earth. The voltage is applied across the switch. The test voltage is applied line side with respect to load side. However if a worker was in direct contact with the wires and earth downstream of the isolation switch that incorporates SwitChek, and the AC supply system has an earth reference (common arrangement), the worker would receive a shock current of < 0.5mA for 0.1 second every 30 seconds which for most people is well below their threshold of perception. In summary, there is no danger upstream or downstream to personnel, VSDs or other equipment as they see no potential difference between phases or appreciable shock current with respect to earth.

Potentially yes, but not likely. This would need to be considered for your installation. The SwitChek Human Machine Interface (HMI) penetration is approximately 25mm in diameter. This penetration is required to fit 1 x 22.5 pilot indicator light. This is certainly a better arrangement than multiple pilot lights or a window for a Visible Break Isolator (VBI).

SwitChek 3 phase Isolation Switch Tester has undergone rigorous laboratory and field testing. Just as manual testing derives its accurate result from the user following a strict, 3 step, testing procedure, so too does SwitChek. However, SwitChek provides the operator with the controls and indications to simply and safely perform the testing procedure.

A failure modes and effects analysis (FMEA) conducted on SwitChek indicated that a single fault within the test system will not impede the safety function and will be detected and indicated to the user. What this means is that SwitChekwill have a long life span typical of all electronic equipment. However, if it should fail it will indicate that the test is invalid because of the failure and that the operator will not be placed at any risk. It will not indicate an isolated state when in fact the circuit is energised.

If you are familiar with Functional Safety eg ISO 13849 the following SwitChek information maybe of benefit:

- ISO 13849-1 – Category 3, PL d

MTTFd = High, DCavg = Medium, CCF = Pass, Structure = Cat 3

Alternatively, If you are familiar with Functional Safety eg IEC 61508 the following SwitChek information maybe of benefit:

Proof Test Interval (Years) | PFD average | Safety Integrity Level (SIL) |

0.5 | 5.86 x 10^-5 | 3/4 |

1.0 | 1.15 x 10^-4 | 3 |

2.0 | 2.29 x 10^-4 | 3 |

λtotal = 491.40 x 10^-9

λsafe = 167.74 x 10^-9

λdangerous = 113.22 x 10^-9

SFF = 95%

No. In fact, testing for dead, live dead live testing, zero voltage verification is a legal requirement in most jurisdictions. There are however good reasons why you should not rely on it to verify an isolation in some cases.

If you need more convincing download a copy of the “Confirming Electrical Isolations” white paper on the DeadEasy page.

SwitChek 3 phase Isolation Switch Tester will not report a deenergised state when in fact the circuit is energised. Should SwitChek fail to satisfy this requirement you will be refunded in full! Including all freight costs!

Under these circumstances Redbusbar reserves the right to inspect the installation and witness the incorrect operation of SwitChek. In addition, damage to or deliberate tampering of SwitChekshall waive this policy.

Anyone. If you can touch the Human Machine Interface (HMI) to activate the self test and read an indication light you can operate SwitChek. No licenses are necessary.

SwitChek installation involves:

- Mount the Human Machine Interface (HMI) on the switchboard panel door. A 22.5mm hole is required.

- Clip the electronics module and star interface on the DIN rail inside the switchboard.

- Plug one end of the HMI connecting cable into the HMI and the other end into the electronics module.

- Connect instrument wiring to the power circuit using crimped boot lace pins / crimped ring terminals or lugs / cable tied lip blade terminals. Connect the other end of the instrument wiring to the star interface plugs.

- Connect wiring between the electronics module plugs and star interface plugs

- Connect 24VDC (0VDC earth referenced) to the electronics module.

Note that there is minimal panel modification and minimal wire stripping and terminating necessary. Our clients have budgeted 45 minutes for the complete installation including isolation.

Not yet. SwitChek 3 phase Isolation Switch Tester was designed to UL61010-1 and offers the following installation performance:

- CAT III, 300VAC (Line to Neutral) equivalent to 424VAC (Line to Line)

These are the options that our clients have used before for SwitChek on a load break switch:

- Most sites incorporate PLCs that are supplied from Uninterruptable Power Supplies (UPS). The UPS often supplies a 24VDC PLC power supply which can also be used to supply SwitChek while the UPS batteries maintain supply. Alternatively you can connect a dedicated 24VDC SwitChek power supply to the UPS.

- A 24VDC battery charger connected to two 12V series connected, sealed motorcycle batteries also works well. You can then take a circuit from the batteries through an in line fuse to power SwitChek .

No. In fact, most isolation verification methods for non-electrical maintenance are non-specific and the regulators do not define “effective means of verification”. This may because it can be different from plant to plant and by specifying methods it tends to shift responsibility back to the regulator in the case of an accident. In these cases, individual inspectors may advise their preferences. Often though, the inspector’s responsibility is limited to checking that what is specifically stated in the regulations is implemented, rather than embellishing the law with their individual ideas. Often the plant operator is better informed than the regulator, and ultimately responsible for what may constitute “effective means of verification”. Essentially, the legislation is often vague enough to allow for SwitChek implementation and endorsement from a regulator is both unlikely and unnecessary.

SwitChek requires a 24VDC, 100mA power supply to illuminate the green LED when the isolator is turned off. Often either within the same panelor in the near vicinity, a control supply is available that can be employed for this purpose. In situations when even this is not available some customers have utilised a small DC UPS such as Phoenix Contact’s MINI-DC-UPS/24DC/2 Part#2866640 which offers 0.8Ah capacity. This device should power one SwitChek for approximately four hours after power is switched off.

Documents

Installation Drawings

Download … Termination Diagram (PDF)

| Weight | 0.7 kg |

|---|---|

| Dimensions | 25 × 25 × 6 cm |

Related products

Isolation Verification

Isolation Verification

Reviews

There are no reviews yet